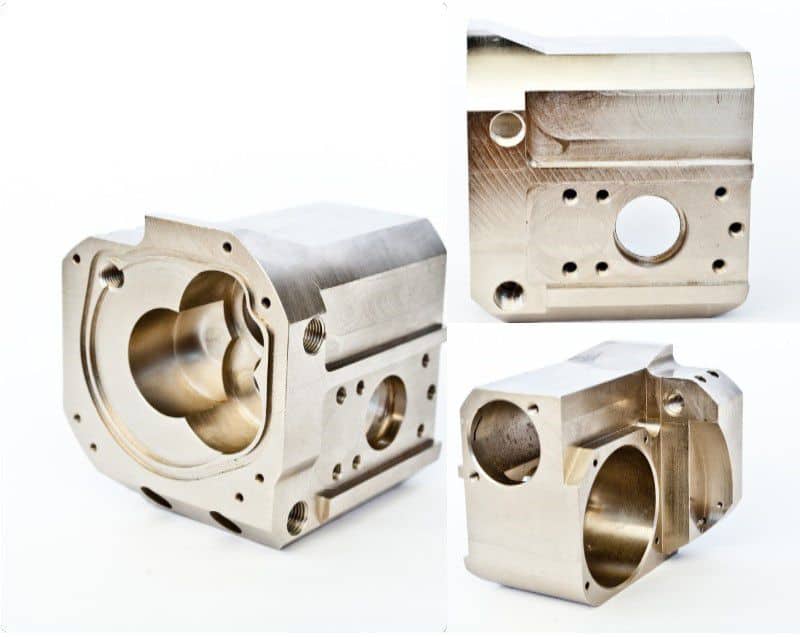

Our Machining Centers combine advanced technology and productivity for a wide variety of applications.

The Mazak Machining centers are equipped with tool-eyes and 4th axis. The MAZAK NEXUS 410B-II Vertical Machining Centers are built with more productivity-enhancing features than any other vertical in its class. They are equipped with Mazatrol Matrix Nexus CNC, providing conversational (EIA programming), enabling capabilities and productivity necessary for our technology driven shop.

CNC Machining Centers (Mills)

Work sizes range up to 20″ X 44″ and tolerances to .0001″.

- (2) MAZAK NEXUS 410B-II Vertical Machining Centers

X-30.00″ Y-16.00″ Z-20.00″ - MAZAK VTC-200B Machining Center

X-44.00″ Y-20.00″ Z-20.00″ - MAZAK VCU-400A-5X 5-Axis CNC Vertical Machining Center

Support Equipment

- Manual Mills – Bridgeports – Featuring tenths resolution DRO

- Manual Lathes – Cincinnati – 15″ x 36″ Work Diameter

- Automatic Saw – Cosen 300NC – 12″ x 12″ Cutoff

- Rawyler Precision Cutoff Saw – 1.2″ dia. Max +/- .001 in length

- Helicoil Insertion and Hardware Presses

- Fixturing, Tooling and Work Holding Equipment and Accessories

- Custom Built Tool Holder Storage

- Assortment of Vibratory Tumblers

- Assortment of Abrasive Blast Cabinets

- Ultrasonic Cleaning Equipment

- Deburring and Parts Washers

From Our Blog

Innovations and Future Trends in CNC 5-Axis Machining

The world of precision CNC machining is constantly evolving, and new innovations continue to shape the future of manufacturing. Here are some exciting developments and future trends: New Technologies and Software Advancements Driving Efficiency Artificial intelligence, machine learning, and advanced simulation software are becoming increasingly …

Read MorePrecision CNC Machining in the Modeling, Simulation, and Training Cluster

As we have discussed in previous articles, precision CNC machining is the backbone of innovation, powering the modeling, simulation, and training cluster. Many of the companies within the Florida High Tech Corridor depend on the precision CNC machining capabilities of a highly qualified machine shop. …

Read MorePrecision CNC Machining and the Florida High Tech Corridor

Precision CNC machining serves as the cornerstone of innovation in the modeling, simulation, and training cluster, especially within the Florida High Tech Corridor. The meticulous craftsmanship and precision offered by CNC machining are indispensable for driving advancements, optimizing production processes, and meeting stringent industry standards. …

Read More