Equipment Prototype Production Machining

Prototype and Production Machining

JW Machine combines advanced technology and productivity

for use in a wide variety of applications.

CNC Machining Centers (Milling)

- MAZAK VCU-400A-5X 5-Axis CNC Vertical Machining Center

Specifications:

Table Size…………………………………………………………… 15.75” diameter

X-Axis Travel……………………………………………………… 19.88”

Y-Axis Travel……………………………………………………… 15.75”

Z-Axis Travel………………………………………………………20.07”

B-Axis Travel (table tilting: indexing 0.0001°)……… + 95° ~ -45°

C-Axis Travel (table rotation: indexing 0.0001°)…. +/- 360°

Spindle Nose to Table Surface (Min/Max)………….. 4.53” / 24.61”

Maximum Table Weight Capacity……………………… 441 LBS

Table Height……………………………………………………… 26.38”

Optional Spindle Speed / Motor (30min.)…………… 12,000 RPM / 15 HP

Spindle Taper……………………………………………………… Taper #40

Rapid Traverse (X,Y,Z)………………………………………… 945 IPM

Number of Tools………………………………………………… 30

Maximum Tool Diameter (adjacent tools)………… 3.15”

Maximum Tool Diameter (no adjacent tools)…… 4.92”

Maximum Tool Length……………………………………… 10.23”

- (2) MAZAK NEXUS 410B Vertical Machining Centers (X-30.00″ Y-16.00″ Z-20.00″)

Equipped with Mazatrol Matrix

Nexus CNC providing Conversational or EIA programming our advanced technology

Productivity and Performance enhancing Intelligent Machine features

High accuracy and productivity for a variety of industry applications

Easy integration of articulated robots for process automation

Rotary/tilt tables

High-Speed (HS) machine configurations

Work sizes up to 20″ X 44″ and tolerances to .0001″

- MAZAK VTC-200B Machining Center (X-44.00″ Y-20.00″ Z-20.00″)

TABLE SIZE: 57″ X 20″

Mazatrol Fusion 640M Control

The VERTICAL TRAVELING COLUMN (VTC) features a powerful 40 Taper spindle

Full traveling column design

Fixed table for machining of extremely long and heavy work pieces

Delivers fast rapid traverse rates to reduce non-cut times.

24 tool storage capacity

Automatic tool changer

CNC Mill Turn Centers (Lathes)

- MAZAK Super Quick Turn 18

3-axis CNC lathe with sub spindle, 2.5″ diameter through, LNS Quick Load magazine loader, Live Tooling

- MAZAK Super Quick Turn 15

3-axis CNC lathe with sub spindle, 2″ diameter through, LNS Quick Load magazine loader, Live Tooling

- MAZAK Super Quick Turn 10

3-axis CNC lathe with sub spindle, 1-5/8″ diameter through, LNS Quick Load magazine loader

- CNC Lathe – MAZAK Quick Turn 8

1.5″ diameter through,

Support Equipment

- Manual Mills – Bridgeports – Featuring tenths resolution DRO

- Manual Lathes – Cincinnati – 15″ x 36″ Work Diameter

- Automatic Saw – Cosen 300NC – 12″ x 12″ Cutoff

- Rawyler Precision Cutoff Saw – 1.2″ dia. Max +/- .001 in length

- Helicoil Insertion and Hardware Presses

- Fixturing, Tooling and Work Holding Equipment and Accessories

- Custom Built Tool Holder Storage

- Assortment of Vibratory Tumblers

- Assortment of Abrasive Blast Cabinets

- Ultrasonic Cleaning Equipment

- Deburring and Parts Washers

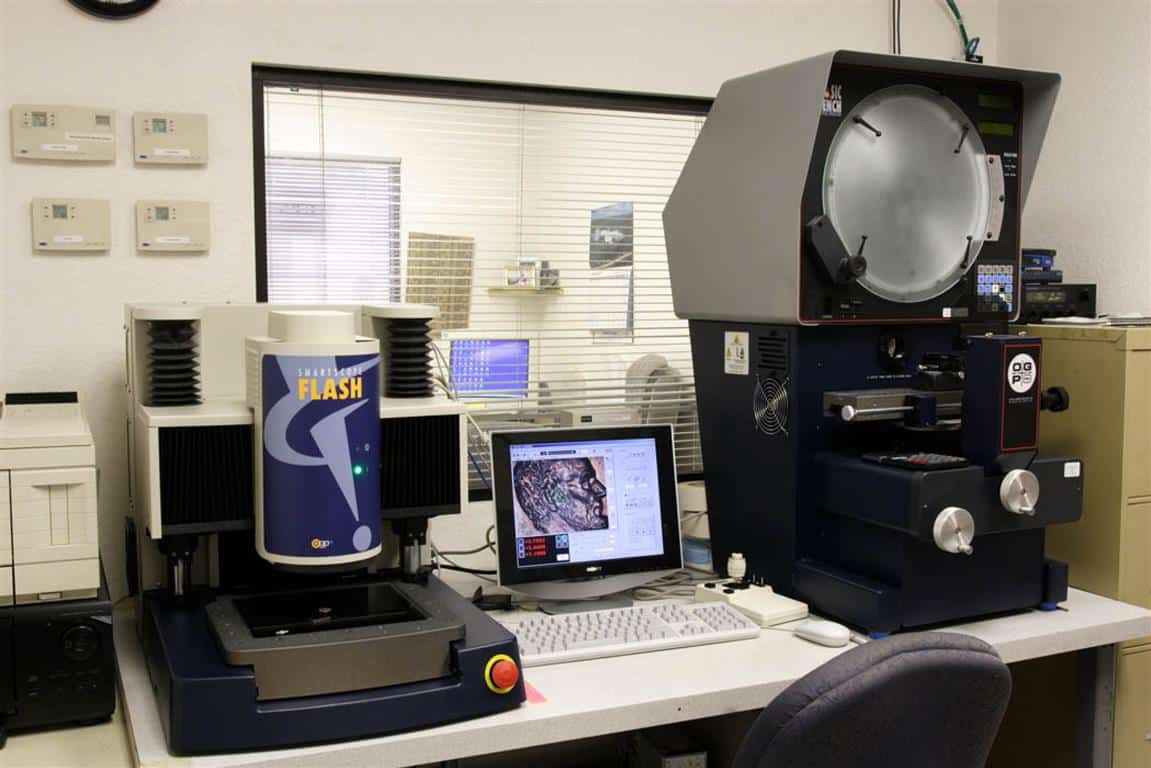

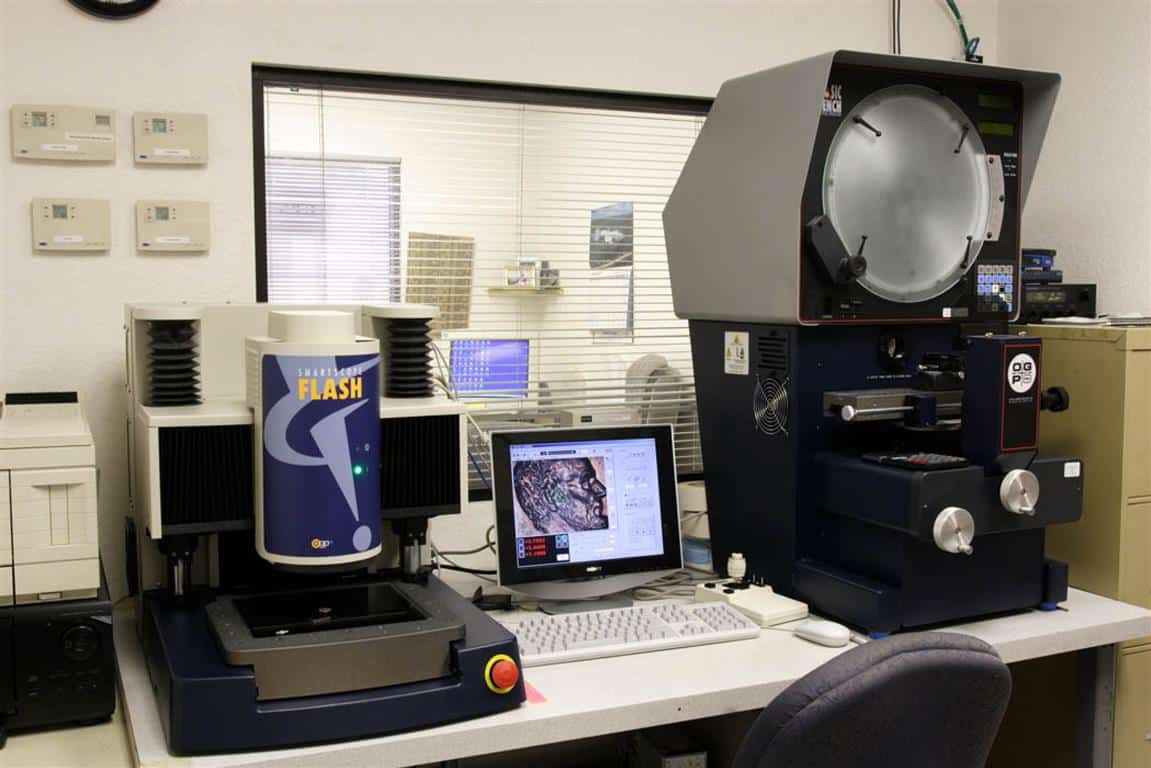

Engineering & Design Center

- SolidWorks CAD software and CAMWorks

- Pro/Engineer

- AutoCAD

- TEK-Soft

- STEP, IGES, DXF, DWG and other file exchange capabilities

- Profile Projectors /Shadow Graph

- Electronic CMM height gauges

- Pin Gauges, Micrometers, and others

Laser Cutting & Engraving Service

- Helix Epilog Laser Engraver

Work Area: 24″ x 18″ (610 x 457 mm)