JW Machine is certified and follows the AS9100 D / ISO 9001:2015 quality standard. This standard ensures critical quality control throughout the entire manufacturing process, providing confirmation that all production parts, components, and assemblies conform with the contractual and design specification requirements of our customers and meets or exceeds most standards required by our aerospace and defense contractor requirements.

JW Machine has a history of providing quality, personalized service to a wide variety of commercial, government, aeronautical and defense contractors throughout the United States and Canada. JW Machine is JCP Certified and registered ITAR Compliant. The AS9100 certification is the requirement for doing business with most Aerospace and Defense customers. The ISO 9001:2015 quality standard is a step up from the older “preventative action” model to the “risk based” thinking model and is currently recognized as the international quality standard and U.S. military specifications to serve defense contracts. Our quality inspection department calibration compliance certificates are available upon request as provided by ISO quality certified inspectors.

Job routers, materials, outside services and inspection procedures are tracked and maintained for traceability. We take great pride in our workmanship, complying with custom specifications, standards and requirements demanded by the market(s) you serve. We promise to provide the highest quality services. Give us an opportunity to prove our promise!

Our Certified Calibrated Precision Inspection department uses:

- AS9100 D / ISO 9001:2015 standards

- Calibrated Inspection Surfaces

- Calibration meets ISO standards

- Quality documentation in 2D and 3D

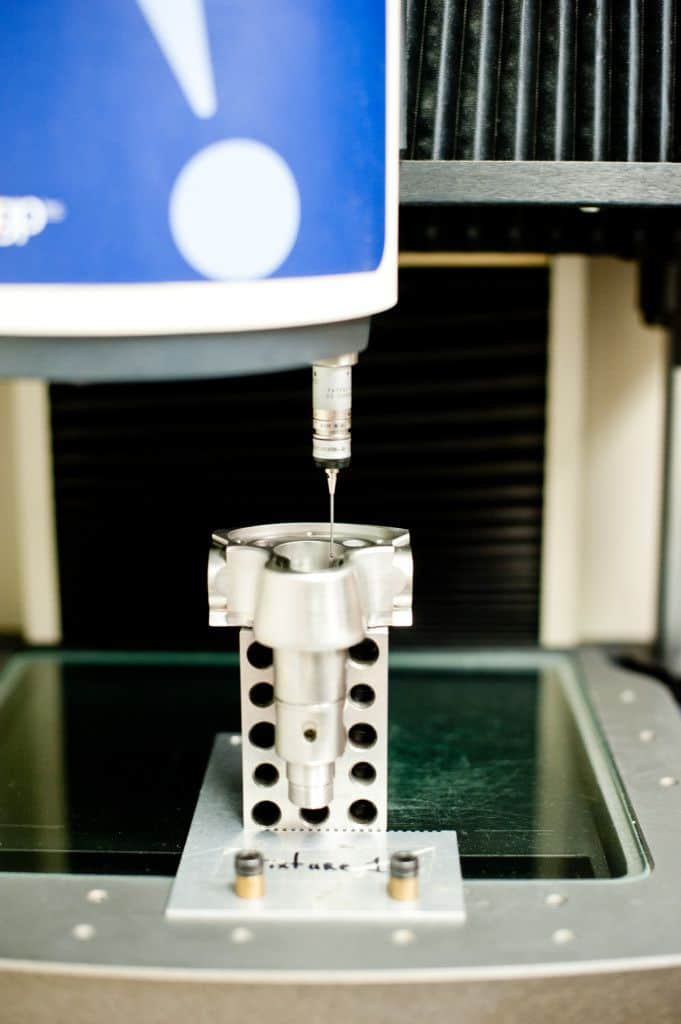

- CMM Electronic Optical and probe – Brown and Sharp 4.5.4 SF (enabling a broader scope of capabilities to include additional LDD activities into our customer service)

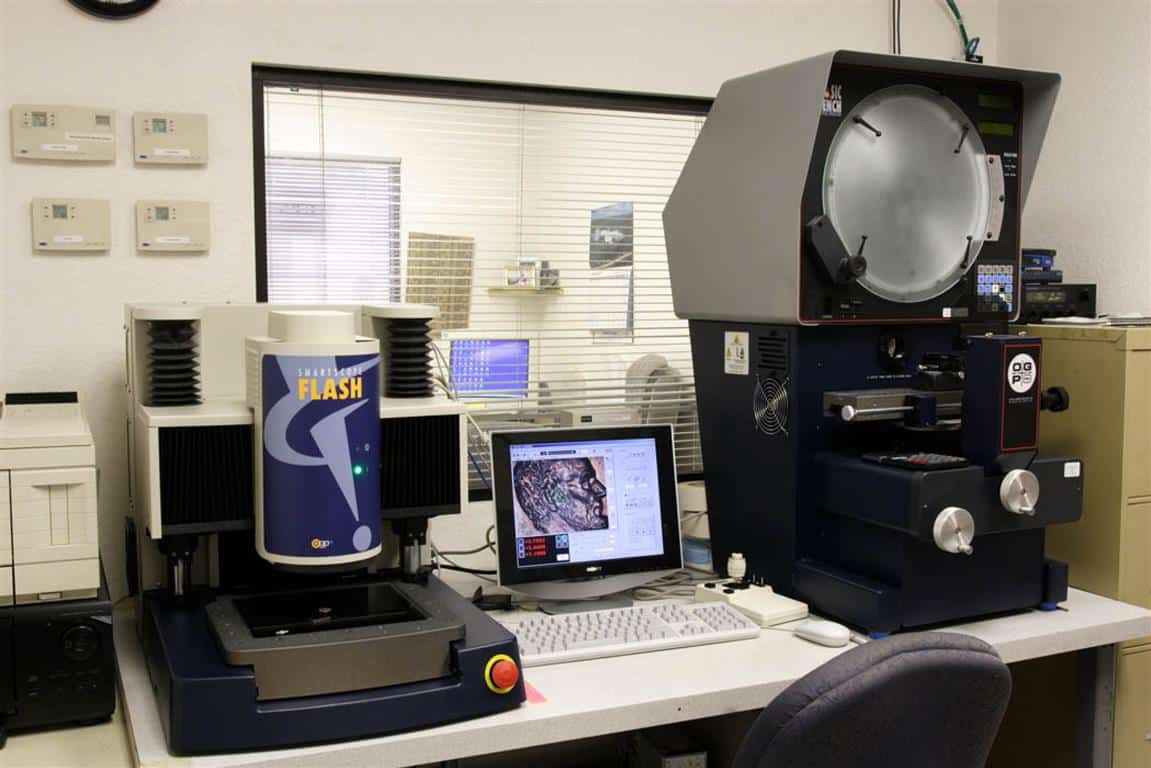

- State-of-the-art Multi-sensor Video Metrology SmartScope – A unique combination to deliver accuracy, repeatability and speed reducing inspection times improving costs

- Precision measuring system using electronic optics, video, and Renishaw touch probe

- A varying range of dial bore gauges, ring gauges, thread gauges, thread plug gauges, micrometers, height gauges, pin gages, indicators

- OGP optical comparator

- Electronic Tesa and Trimos Digital height inspection gauges