What Matters in Precision CNC Machining: Quality and Accuracy Standards

When it comes to precision CNC machining, quality and accuracy are non-negotiable factors that can make or break the success of your project. A reputable precision CNC machining facility like JW Machine adheres to stringent quality control processes and consistently delivers parts that meet or …

Read MoreThe Importance of Choosing the Right Precision CNC Machining Facility

Selecting the right precision CNC machining facility is a critical decision that can significantly impact the quality, efficiency, and overall success of your manufacturing project. The right precision CNC machining facility not only offers advanced machinery and skilled technicians but also understands the specific requirements …

Read MoreUnderstanding the Basics of Precision CNC Machining

Precision CNC machining is a highly specialized manufacturing process that uses computer-controlled machines to produce complex and accurate parts with tight tolerances. Unlike manual machining methods, CNC (Computer Numerical Control) technology allows for exceptional repeatability and precision, making it ideal for industries where exact specifications …

Read MoreFuture Trends in Precision CNC Machining Centers

As technology continues to evolve at a rapid pace, the future of precision CNC machining centers like the Mazak Integrex 100-4S is poised to be shaped by several exciting trends. One of the most significant developments is the integration of advanced automation, which will enable …

Read MoreUnlocking Potential with the Mazak Integrex 100-4S CNC Machining Center

The Mazak Integrex 100-4S CNC machining center stands as a true game-changer in the world of precision manufacturing. Combining multi-tasking capabilities with advanced technology, it empowers manufacturers to tackle complex parts with unmatched efficiency and accuracy. Whether you’re producing intricate aerospace components, defense parts, precision …

Read MoreComparing the Mazak Integrex 100-4S CNC Machining Center to Other Types of Precision CNC Machining Equipment

When evaluating the Mazak Integrex 100-4S against other types of precision CNC machining centers, it quickly becomes clear why this model stands out in precision and versatility. Unlike some types of multi-axis machining centers that focus on either turning or milling, the Mazak Integrex 100-4S …

Read MoreProductivity and Efficiency Benefits of the Mazak Integrex 100-4S CNC Machining Center

One of the standout advantages of the Mazak Integrex 100-4S CNC machining center is its remarkable ability to significantly boost productivity and operational efficiency. This advanced multi-tasking machine combines CNC turning, milling, and drilling capabilities in a single setup, drastically reducing the need for multiple …

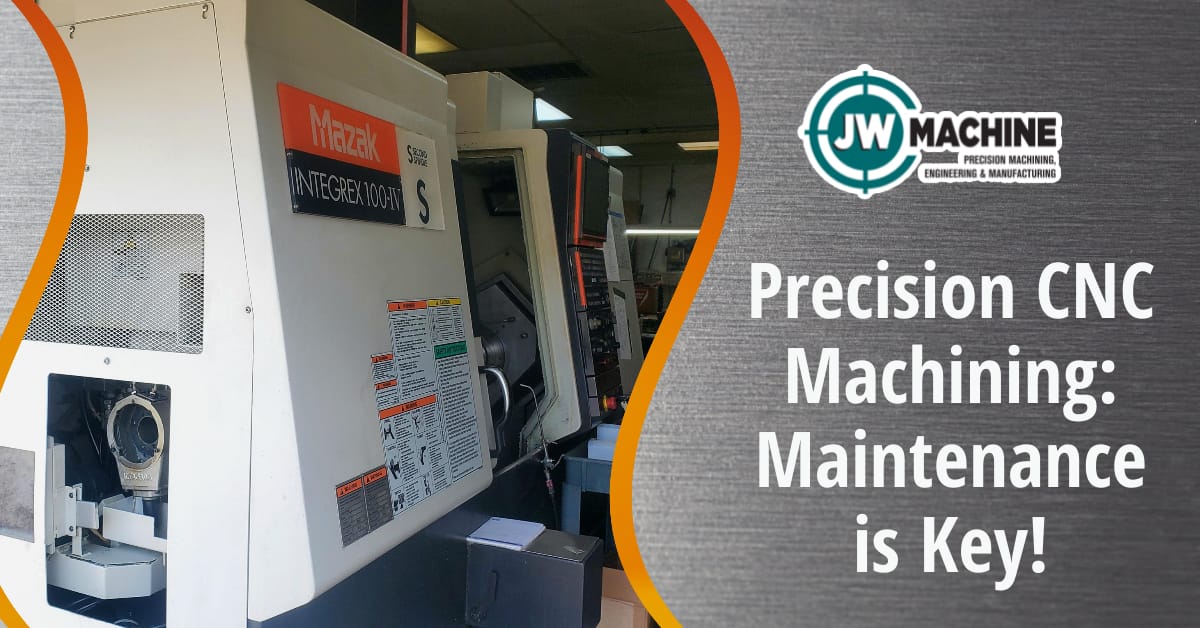

Read MorePrecision CNC Machining: Maintenance is Key!

JW Machine is a leading and trusted machine shop that prides itself on ensuring its precision CNC machining equipment is properly maintained and ready to handle any prototypes to production manufacturing and contract manufacturing projects that come their way! The Mazak Integrex 100-4S requires a …

Read MoreMazak Integrex 100-4S CNC Machining Center: Applications and Industries Served

The Mazak Integrex 100-4S CNC machining center is renowned for its versatility and precision, making it an invaluable asset for precision CNC machining across a wide range of industries. Its unique multi-tasking capabilities allow for complex parts to be machined in a single setup, significantly …

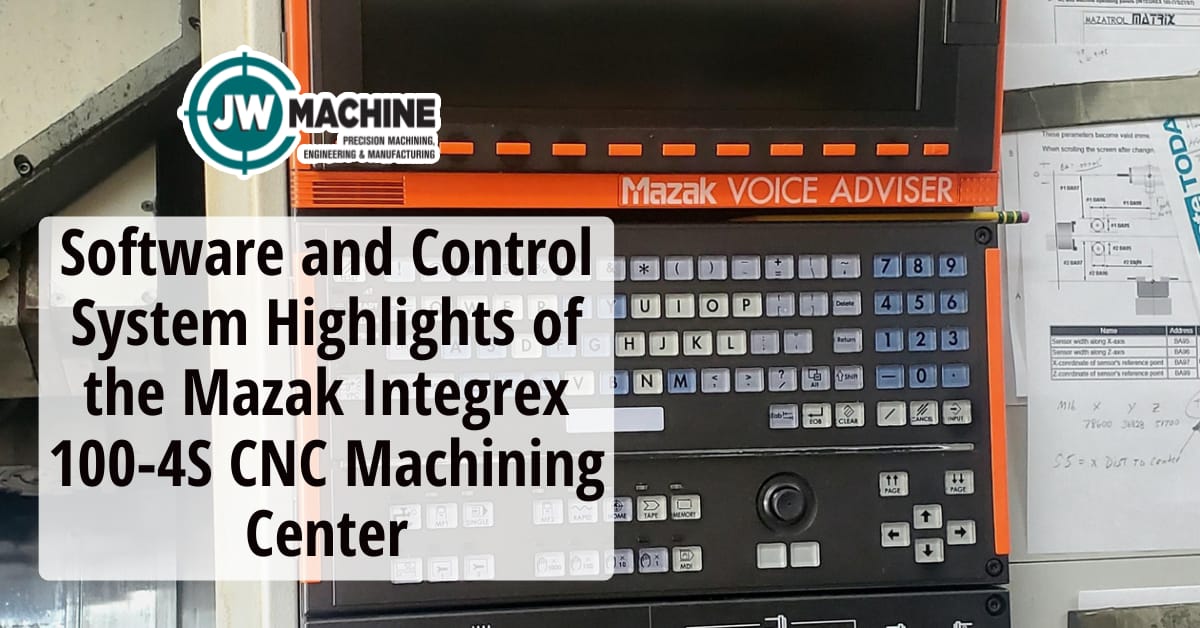

Read MoreSoftware and Control System Highlights of the Mazak Integrex 100-4S CNC Machining Center

The Mazak Integrex 100-4S is equipped with an advanced software and control system that truly elevates its precision CNC machining capabilities. At the heart of its operation lies the Mazak SmoothX CNC control, renowned for its intuitive interface and powerful processing abilities. This control system …

Read More

Connect with us: