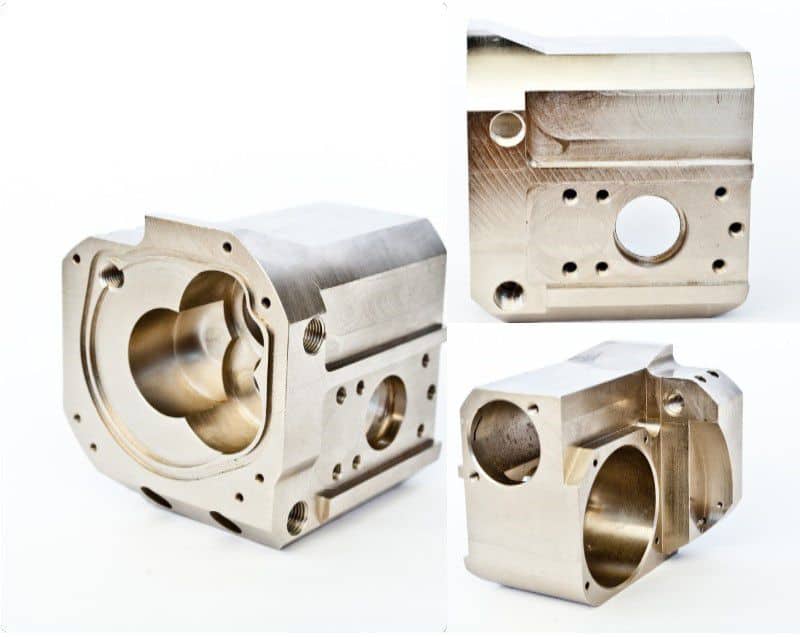

Our Machining Centers combine advanced technology and productivity for a wide variety of applications.

The Mazak Machining centers are equipped with tool-eyes and 4th axis. The MAZAK NEXUS 410B-II Vertical Machining Centers are built with more productivity-enhancing features than any other vertical in its class. They are equipped with Mazatrol Matrix Nexus CNC, providing conversational (EIA programming), enabling capabilities and productivity necessary for our technology driven shop.

CNC Machining Centers (Mills)

Work sizes range up to 20″ X 44″ and tolerances to .0001″.

- (2) MAZAK NEXUS 410B-II Vertical Machining Centers

X-30.00″ Y-16.00″ Z-20.00″ - MAZAK VTC-200B Machining Center

X-44.00″ Y-20.00″ Z-20.00″ - MAZAK VCU-400A-5X 5-Axis CNC Vertical Machining Center

Support Equipment

- Manual Mills – Bridgeports – Featuring tenths resolution DRO

- Manual Lathes – Cincinnati – 15″ x 36″ Work Diameter

- Automatic Saw – Cosen 300NC – 12″ x 12″ Cutoff

- Rawyler Precision Cutoff Saw – 1.2″ dia. Max +/- .001 in length

- Helicoil Insertion and Hardware Presses

- Fixturing, Tooling and Work Holding Equipment and Accessories

- Custom Built Tool Holder Storage

- Assortment of Vibratory Tumblers

- Assortment of Abrasive Blast Cabinets

- Ultrasonic Cleaning Equipment

- Deburring and Parts Washers

From Our Blog

Understanding the Basics of Precision CNC Machining

Precision CNC machining is a highly specialized manufacturing process that uses computer-controlled machines to produce complex and accurate parts with tight tolerances. Unlike manual machining methods, CNC (Computer Numerical Control) technology allows for exceptional repeatability and precision, making it ideal for industries where exact specifications …

Read MoreFuture Trends in Precision CNC Machining Centers

As technology continues to evolve at a rapid pace, the future of precision CNC machining centers like the Mazak Integrex 100-4S is poised to be shaped by several exciting trends. One of the most significant developments is the integration of advanced automation, which will enable …

Read MoreUnlocking Potential with the Mazak Integrex 100-4S CNC Machining Center

The Mazak Integrex 100-4S CNC machining center stands as a true game-changer in the world of precision manufacturing. Combining multi-tasking capabilities with advanced technology, it empowers manufacturers to tackle complex parts with unmatched efficiency and accuracy. Whether you’re producing intricate aerospace components, defense parts, precision …

Read More