One of the standout features of the Mazak Integrex 100-4S precision CNC machining center is its exceptional multi-tasking capabilities, which revolutionize the way complex parts are manufactured. Unlike traditional machining centers that require multiple setups and machines, the Mazak Integrex 100-4S seamlessly combines CNC turning, CNC milling, and drilling operations into a single, compact machine. This integration allows for simultaneous processing on multiple axes, significantly reducing production time and increasing overall efficiency.

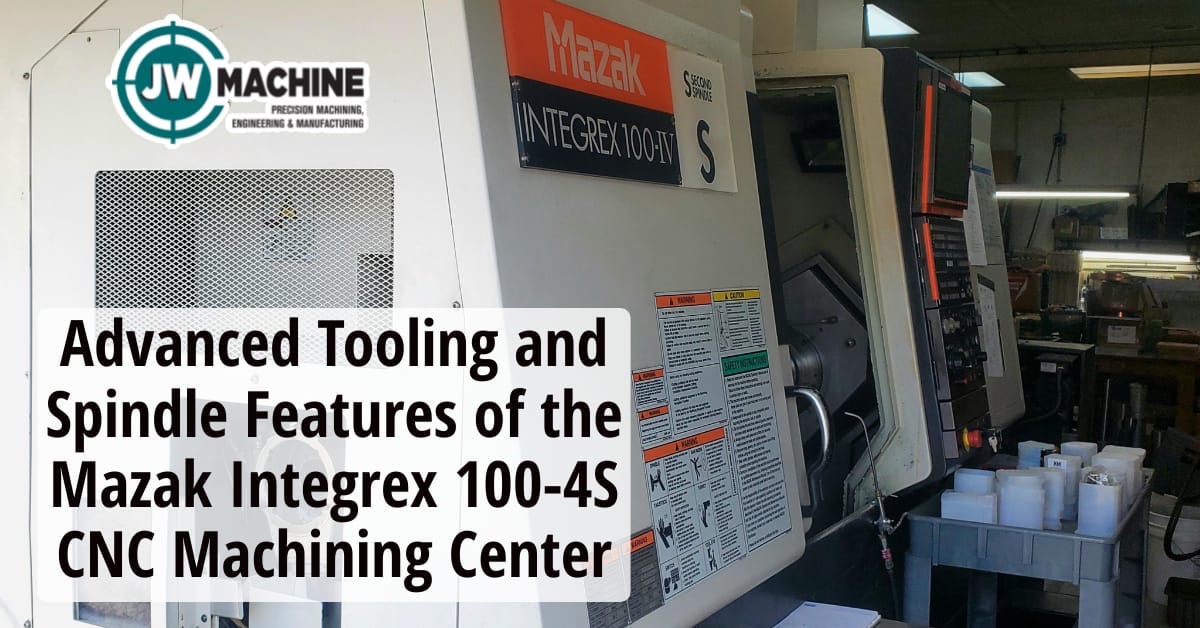

Equipped with both a main spindle and a sub-spindle, the Mazak Integrex 100-4S can perform two-sided machining without the need to manually reposition the workpiece. This not only enhances precision but also minimizes human error and setup times. Additionally, its advanced tool turret and live tooling enable the execution of intricate cutting tasks, including contouring and complex hole-making, all within the same cycle.

The machine’s ability to handle multi-axis machining tasks means the machinists at JW Machine can produce highly detailed and geometrically complex components in fewer steps, often achieving what would traditionally require multiple machines. This capability is especially valuable in industries such as aerospace, OEM parts, defense, and medical device manufacturing, where precision and efficiency are paramount.

JW Machine distinguishes itself through its extensive expertise across multiple sectors. Our vast capabilities include 5-Axis machining, CNC turning, CNC milling, close tolerance machining, small part machining, laser cutting, laser engraving, and more. Regardless of the size or complexity of your project, JW Machine is ready to support all of your contract manufacturing and prototypes to production manufacturing needs. Give your friends at JW Machine a call to learn more today!