Why CNC Machining?

The primary purpose of using computer numerical control (CNC) is tool control, which produces a more accurate end result. A CNC machine shop relies on tool control for processes such as milling turning, close tolerance machining, small part machining, laser cutting, laser etching and laser …

Read MoreCOVID-19 Notice

Normal Operating Schedule Yesterday Gov. Ron DeSantis issued a safer-at-home order for the next 30 days for the State of Florida. JW Machine would like to let everyone know that we are operating under our normal operating schedule under the orders for essential business operations. …

Read MoreSmall Part Machining… It’s All About the Lubricant

Part One Small part machining to tolerances of one ten thousandth of an inch presents multiple challenges. All milling turning processes require some form of lubrication. In previous articles we have discussed the differences between milling turning processes, climate control, and material selection. Now, let’s …

Read MoreMilling Turning – Similar but Different

Some people associate the term milling turning with one single process. While both are conventional machining processes, milling and turning use different types of cutters and produce contrasting end results. Part one of our series discussed milling turning differences. This article focuses on some of …

Read MoreMilling Turning – The Differences Explained

Although milling turning is a common term used in precision CNC machining, they are actually separate processes. Part one of our article will discuss milling turning and some of the differences between these two types of conventional machining operations. Cutting Tool The cutting tool for …

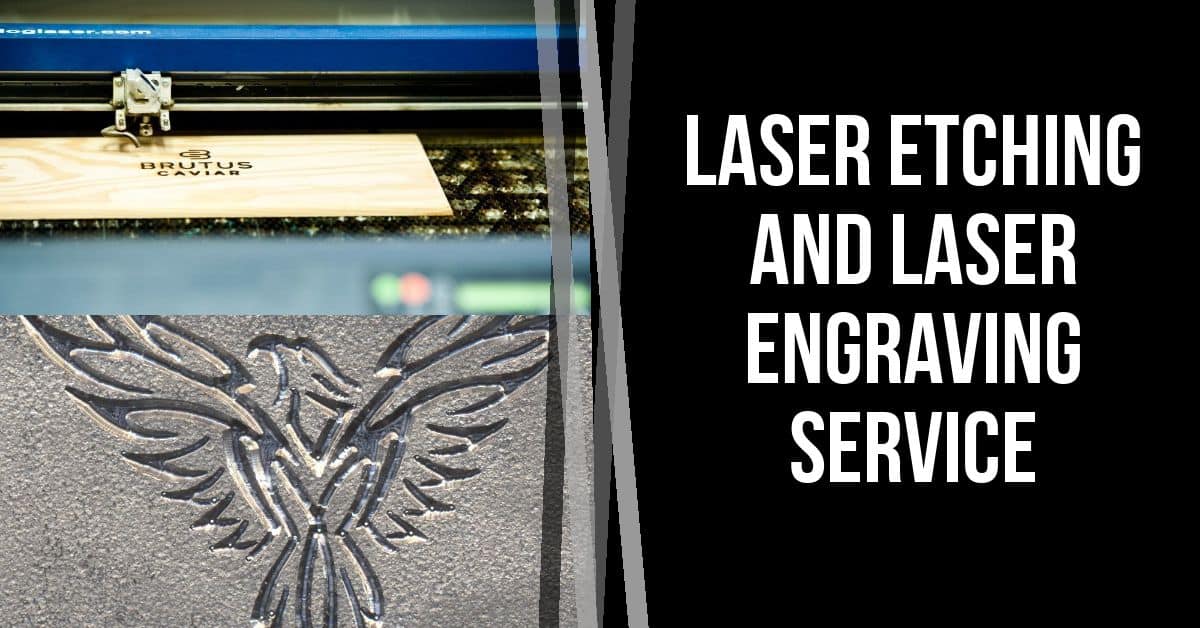

Read MoreLaser Etching and Laser Engraving Service

Laser etching and laser engraving are two of our most popular services. Our qualified operators perform these services using our Helix Epilog Laser Engraver. This advanced equipment has a proven track record in laser etching and laser engraving on a variety of materials including anodized …

Read MoreLaser Cutting vs. Plasma Cutting

There are distinct differences between laser cutting and plasma cutting. Plasma cutting was developed in the 1950s specifically for metals that could not be cut by a flame including copper, stainless steel and aluminum. The torch of a plasma cutting machine uses high velocity gas …

Read MoreWhy JW Machine is an Industry Leader in Small Part Machining

Small part machining is an art in itself. The smaller the part, the bigger the challenges, which is why industries such as aerospace, energy, aviation, high performance racing, photonics, Department of Defense and the military trust JW Machine with their small part machining needs. Let’s …

Read MoreFeatured Service: Milling Turning

This month our featured service will focus on milling turning services for contract manufacturing. In a previous article, we discussed how milling turning processes differ. Today, we will concentrate on milling turning services provided by JW machine. Before you commit to contract manufacturing for a …

Read MoreLaser Engraving Service – Precision Matters!

JW Machine is proud to work with the Department of Defense and industries including aerospace, simulation and telecommunication to fulfill their contract manufacturing needs. In many cases, the parts we produce for these industries are very sensitive and there is no room for mistakes! This …

Read More

Connect with us: